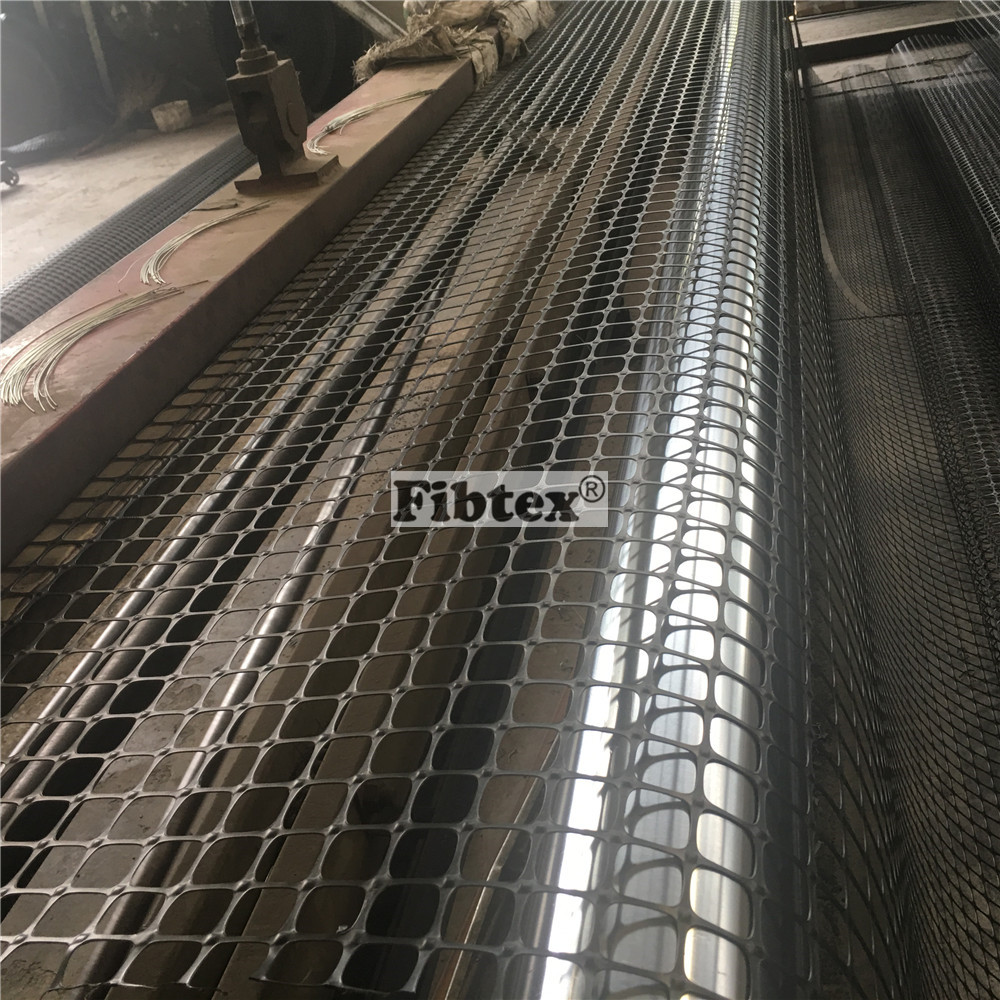

Polypropylene BX Geo Grid

Polypropylene BX Geo Grids can improve bearing capacity of foundation, Preventing cracking and subsiding.Convenient to construct, reducing cost and maintaining expense. Polypropylene BX Geogrids have been approved CE certificate and exported to more than 50 countries and regions.

Certificate: ISO9001, CE

Features:

- Reducing aggregate fill thicknesses

- Reducing sub-excavation

- Simplifying construction

- Extending service life of pavement

- Reducing labour

- Reducing equipment requirements

- Improving bearing capacity of foundation

- Preventing cracking and subsiding

- Convenient to construct, reducing cost and mantaining expense

Improved performance for:

- Municipal roads

- Highways

- Railway ballast

- Site access roads

- Haul roads

- Parking lots

- Industrial shipping yards

- Foundation footings- and more

Application

• Base reinforcement • Subgrade reinforcement

• Slope reinforcement • Embankment stabilization

• Road Reinforcement • Expressway Reinforcement

• Railway Reinforcement • Port Reinforcement

• Airport Reinforcement • Landfill Reinforcement

• Irrigation Project • Sea Reclamation Project

BX2525 Technical Specifications

|

Specification |

Test Method |

Unit |

BX1515 |

BX2020 |

BX2525 |

BX3030 |

BX4040 |

BX1100 |

BX1200 |

BX3030L |

||||||||

|

Index |

|

Unit |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

MD |

TD |

|

Ultimate Tensile Strenth |

D6637 |

KN/m |

15 |

15 |

20 |

20 |

25 |

25 |

30 |

30 |

40 |

40 |

12.4 |

19.0 |

19.2 |

28.8 |

30 |

30 |

|

Aperture Size |

|

mm |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

39 36 33 31 |

25 |

33 |

25 |

33 |

65 |

65 |

|

Minimum Rib Thickness |

|

mm |

1.0 |

0.8 |

1.5 |

1.1 |

1.8 |

1.4 |

2.2 |

1.7 |

2.5 |

2.0 |

1.0 |

0.8 |

1.4 |

1.27 |

1.7 |

1.5 |

|

Tensile Strength @2% Strain |

D6637 |

KN/m |

6 |

6 |

7 |

7 |

9 |

9 |

11 |

11 |

15 |

15 |

4.1 |

6.6 |

6 |

9 |

11 |

11 |

|

Tensile Strength @5% Strain |

D6637 |

KN/m |

11 |

11 |

13 |

13 |

17 |

17 |

21 |

21 |

27 |

27 |

8.5 |

13.4 |

11.8 |

19.6 |

21 |

21 |

|

Junction Efficiency |

|

% |

95 |

95 |

95 |

95 |

95 |

95 |

95 |

95 |

||||||||

|

Flexural Stiffness |

D7748 |

mg-cm |

690,000 |

780,000 |

860,000 |

960,000 |

1,000,000 |

250,000 |

750,000 |

960,000 |

||||||||

|

Aperture Stability |

|

m-N/deg |

0.30 |

0.50 |

0.62 |

0.75 |

0.85 |

0.32 |

0.65 |

0.75 |

||||||||

|

Resistance to Installation Damage |

|

SC/SW/GP |

95/93/90 |

95/93/90 |

95/93/90 |

95/93/90 |

95/93/90 |

95/93/90 |

95/93/90 |

95/93/90 |

||||||||

|

Resistance to Long Term Degradation |

|

% |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

||||||||

|

Resistance to UVDegradation |

D4355 |

% |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

||||||||

|

Minimum Cabon Black |

|

% |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

||||||||

|

Unit Weight |

|

g/m2 |

175-210 |

220-250 |

260-300 |

300-340 |

450-500 |

180-210 |

280-310 |

320-360 |

||||||||

|

Rolls Dimensions (Length, Width) |

|

m |

100*3.95 100*5 100*5.95 |

50*3.95 50*5 50*5.95 |

50*3.95 50*5 50*5.95 |

50*3.95 50*5 50*5.95 |

50*3.95 |

75*3.95 75*5 75*5.95 |

50*3.95 50*5 50*5.95 |

50*3.95 50*5 50*5.95 |

||||||||

Note: MD = Machine Direction; TD = Transverse Direction

Fibtex Laboratory is improving continuously with the purpose of assuring reliable quality.Geotec geosynthetics reserves the right to change the product specifications without further notification.

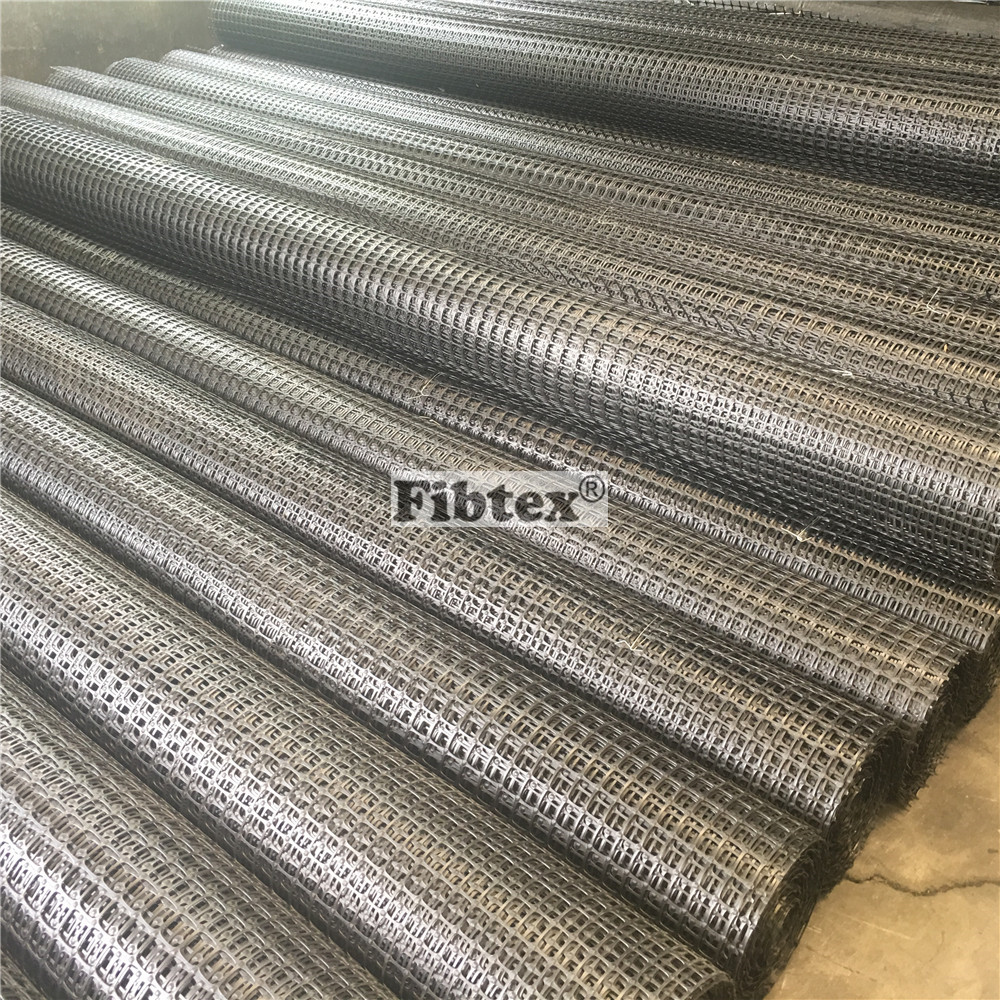

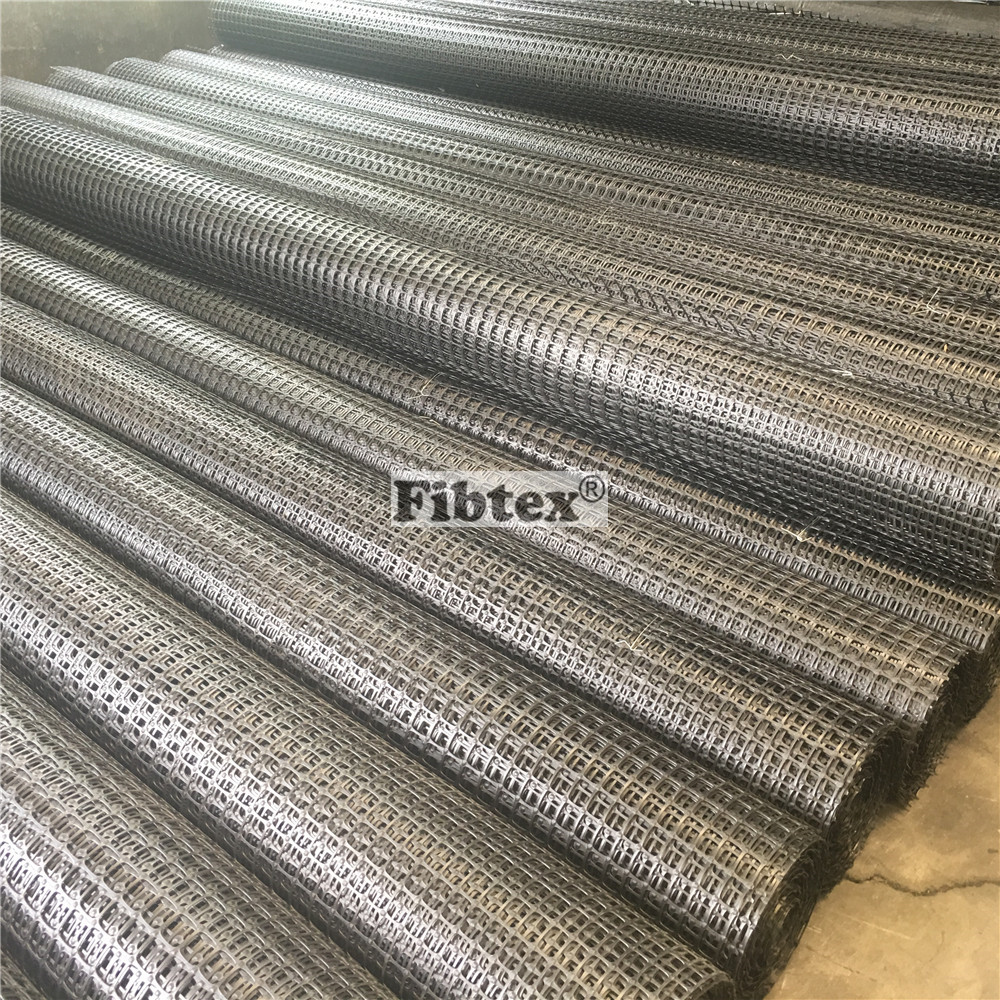

Package

- Straps for rolls tightening.

- Tape used as per requirement.

Loading Capacity For One 40HC Container

|

Product |

Rolls |

Quantity |

|

GG1515 |

180 |

53,325.0 m2 |

|

GG2020 |

220 |

43,450.0 m2 |

|

GG3030 |

130 |

25,675.0 m2 |

|

GG4040 |

90 |

17,775.0 m2 |

Loading Photos

Additional Info

| Packaging: | Nude | Productivity: | 150,000 sqm / day |

| Brand: | Fibtex | Transportation: | Ocean,Land,Air,Fedex etc. |

| Place of Origin | Shandong, China | MOQ | 1x40HC |

| HS Code | 39269090.90 | Port: | Qingdao |