Warp Knitted Fiberglass Geogrid Mesh

The polymer coating allows higher compatibility and adhesion with asphalt, longer-lasting mechanical performance and protection against various chemicals and abrasive materials. Based on field experience, big differences in coating quality exist between Fiberglass Geogrid Mesh products available on the market. Warp Knitted Fiberglass Geogrid we offered are used CTG or Jushi first grade E-glass roving and impregnated by modified asphalt polymer. Fiber Glass Geogrid has been exported to more than 40 countries and regions.

Certificates: ISO9001, CE, ITB

Features and Benefits of Warp Knitted Fiberglass Geogrid Mesh

• Lowers maintenance costs

• Repairs severely cracked roads and postpones complete reconstruction

• Dramatically extends the life of roads, runways and parking lots

• Open aperture design promotes aggregate interlock between paving courses, greatly decreasing shear potential that is common with paving fabrics

• High stiffness, high modulus of elasticity, low elongation

• Effective bonding of grid during installation to leveling course with patented adhesive backing (standard practice of use of tack coat is recommended to enhance or promote bonding between lifts of ACC layers)

• Ease of constructability allows for Fibgrid installation and immediate placement of overlying pavement

• Suitable for all types of asphalt mixes.

• Minimizes both thermal and stress related reflective cracking.

• Reduces pavement rutting under high ambient temperatures and intense wheel loads.

• Increases the fatigue life of pavements with weak foundations.

• Extends pavement life.

• Provides cost benefits by increasing pavement life cycle.

• Fast, easy installation and recyclable.

• Reduces overlay thickness to a minimum of 50 mm.

Applications:

1. Airport runways, taxiways, roads, bridges, parking lots, jointed concrete highways to control reflective cracking.

2. High traffic pavement to control of rutting.

3. New highway construction, and other road maintenance/repair jobs to improve pavement life.

Technical Date:

|

Technical Data of Fiberglass Geogrid Mesh |

|||||||||

|

Specification |

Tensile Strength (kN/m) |

Elongation |

Mesh size (mm x mm) |

Width (m)

|

Roll Length (m) |

Elastic Modulus (Gpa) |

Temperature Resistance |

||

|

Warp |

Weft |

Warp |

Weft |

||||||

|

FG2525 |

≥ 25 |

≥ 25 |

≤ 3 |

≤ 3 |

12.7x12.7 25.4x25.4 30x30 40x40 50x50

|

1 1.5 2 2.5 3 4 4.5 5 6

|

50 100 150 200 300 400 500 600 |

76 |

-100°C-280°C |

|

FG3030 |

≥ 30 |

≥ 30 |

≤ 3 |

≤ 3 |

|||||

|

FG4040 |

≥ 40 |

≥ 40 |

≤ 3 |

≤ 3 |

|||||

|

FG5050 |

≥ 50 |

≥ 50 |

≤ 3 |

≤ 3 |

|||||

|

FG6060 |

≥ 60 |

≥ 60 |

≤ 3 |

≤ 3 |

|||||

|

FG8080 |

≥ 80 |

≥ 80 |

≤ 3 |

≤ 3 |

|||||

|

FG9090 |

≥ 80 |

≥ 80 |

≤ 3 |

≤ 3 |

|||||

|

FG100100 |

≥ 100 |

≥ 100 |

≤ 3 |

≤ 3 |

|||||

|

FG120120 |

≥ 120 |

≥ 120 |

≤ 3 |

≤ 3 |

|||||

|

FG150150 |

≥ 150 |

≥ 150 |

≤ 3 |

≤ 3 |

|||||

|

FG180180 |

≥ 180 |

≥ 180 |

≤ 3 |

≤ 3 |

|||||

|

FG200200 |

≥ 200 |

≥ 200 |

≤ 3 |

≤ 3 |

|||||

|

FG300300 |

≥ 300 |

≥ 300 |

≤ 3 |

≤ 3 |

|||||

|

FG400400 |

≥ 400 |

≥ 400 |

≤ 3 |

≤ 3 |

|||||

|

Physical and Chemical Stability |

Good |

||||||||

|

Pressure Sensative Glue |

Available |

||||||||

|

Coating Material |

Modified Asphalt Polymer, Acrylic Acid Polymer, SBR or PVC |

||||||||

|

Resin Content (%) |

More than 20% |

||||||||

|

Composited or Sewed with Non-Woven Fabric or Geotextile |

25g, 30g, 40g or 50g/m2 PP no-woven fabric with one side or two side by pressure sensative glue or warp knitted 100g/m2, 120g/m2 or 140g/m2 Polyester continous filament needle punched geotextile by warp knitted |

||||||||

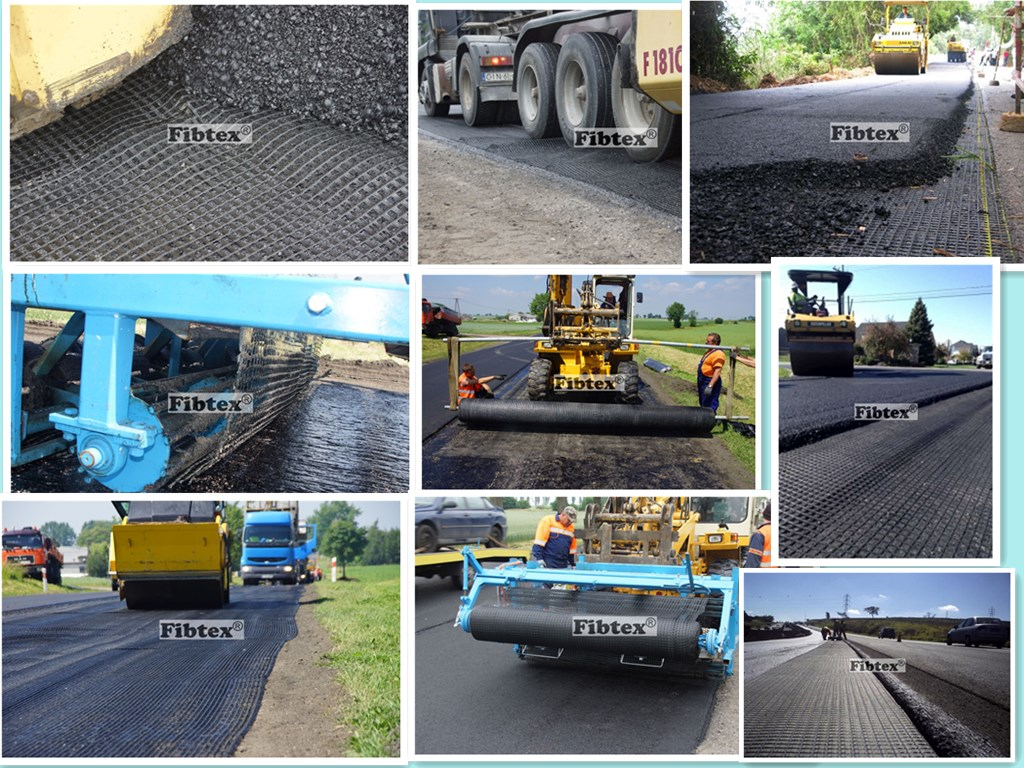

Loading photos

Additional Info

| Packaging: | Cardboard/PVC tube + PE film | Productivity: | 200,000 sqm / day |

| Brand: | Fibtex | Transportation: | Ocean,Land,Air,Fedex etc. |

| Place of Origin | Shandong, China | MOQ | 1x40HC |

| HS Code | 70195900.00 | Port: | Qingdao |