Fiberglass Geogrid Composite with Non Woven Geotextile

The nonwoven acts as an interface between the tack coat and the tires of vehicles during construction. It can absorb an excess of binder of the tack coat and help to better distribute it. Moreover, the light polyester non-woven allows aggregates of the asphalt mixtures to pass through easily and thus ensures aggregate interlocking between layers. When a watertight seal of the underlying pavement structure is required and on uneven bases, such as milled surfaces or concrete structures, a heavier nonwoven geotextile( PP or Polyester) or fabric (more than 100g/m²) combined with regular glass grid can be used. In such a Fiberglass Geogrid Composite Geotextile, the bitumen-impregnated nonwoven is designed to have a SAMI effect and the grid a reinforcing function.

Certificates: ISO9001, CE, ITB

Features and Benefits of Fiberglass Geogrid Composite Non Woven

1. High tensile strength and low elongation rate;

2. High elasticity modulus;

3. Good temperature resistance;

4. High water permeability and anti-filtration

5. Tear resistance and de-dispersion with long service life.

6. As the base material of geogrid composite, non-woven fabric or non-woven geotextile has a fluffy structure and superior drainage performance.

7. The products has good friction coefficient with other base materials, thus the geogrid composite is mainly used for soil reinforcement.

8.It combines all the functions of a geogrid and geotextile in one single product. For this reason, the main area of use for it is on weak subsoils where, in addition to stabilisation and reinforcement, filter and separating properties are required. As a rule, this means subsoils with a CBR value of less than 3 %. Thus, the areas of application for they are to be found in the reinforcement of base courses, foundations, access roads, pipeline trenches and throughout the road building sector. The range of products available incorporates different degrees of tensile strength and covers a variety of applications.

Applications:

1. Airport runways, taxiways, roads, bridges, parking lots, jointed concrete highways to control reflective cracking.

2. High traffic pavement to control of rutting.

3. New highway construction, and other road maintenance/repair jobs to improve pavement life.

Technical Date:

|

Fiberglass Geogrid Geocomposite Technical Data |

|||||||||

|

Specification |

Tensile Strength (kN/m) |

Elongation |

Mesh size (mm x mm) |

Width (m)

|

Roll Length (m) |

Elastic Modulus (Gpa) |

Temperature Resistance |

||

|

Warp |

Weft |

Warp |

Weft |

||||||

|

FG2525 |

≥ 25 |

≥ 25 |

≤ 3 |

≤ 3 |

12.7x12.7 25.4x25.4 30x30 40x40 50x50

|

1 1.5 2 2.5 3 4 4.5 5 6

|

50 100 150 200 300 400 500 600 |

76 |

-100°C-280°C |

|

FG3030 |

≥ 30 |

≥ 30 |

≤ 3 |

≤ 3 |

|||||

|

FG4040 |

≥ 40 |

≥ 40 |

≤ 3 |

≤ 3 |

|||||

|

FG5050 |

≥ 50 |

≥ 50 |

≤ 3 |

≤ 3 |

|||||

|

FG6060 |

≥ 60 |

≥ 60 |

≤ 3 |

≤ 3 |

|||||

|

FG8080 |

≥ 80 |

≥ 80 |

≤ 3 |

≤ 3 |

|||||

|

FG9090 |

≥ 80 |

≥ 80 |

≤ 3 |

≤ 3 |

|||||

|

FG100100 |

≥ 100 |

≥ 100 |

≤ 3 |

≤ 3 |

|||||

|

FG120120 |

≥ 120 |

≥ 120 |

≤ 3 |

≤ 3 |

|||||

|

FG150150 |

≥ 150 |

≥ 150 |

≤ 3 |

≤ 3 |

|||||

|

FG180180 |

≥ 180 |

≥ 180 |

≤ 3 |

≤ 3 |

|||||

|

FG200200 |

≥ 200 |

≥ 200 |

≤ 3 |

≤ 3 |

|||||

|

FG300300 |

≥ 300 |

≥ 300 |

≤ 3 |

≤ 3 |

|||||

|

FG400400 |

≥ 400 |

≥ 400 |

≤ 3 |

≤ 3 |

|||||

|

Physical and Chemical Stability |

Good |

||||||||

|

Pressure Sensative Glue |

Available |

||||||||

|

Coating Material |

Modified Asphalt Polymer, Acrylic Acid Polymer, SBR or PVC |

||||||||

|

Resin Content (%) |

More than 20% |

||||||||

|

Composited or Sewed with Non-Woven Fabric or Geotextile |

25g, 30g, 40g or 50g/m2 PP no-woven fabric with one side or two side by pressure sensative glue or warp knitted 100g/m2, 120g/m2 or 140g/m2 Polyester continous filament needle punched geotextile by warp knitted |

||||||||

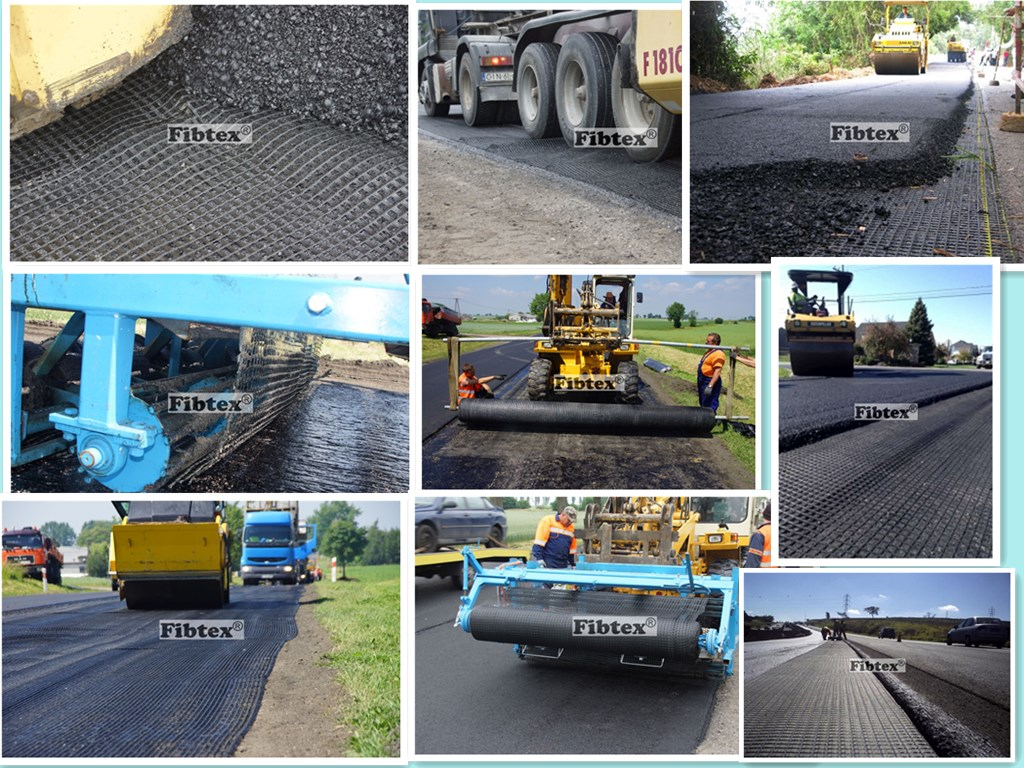

Loading photos

Additional Info

| Packaging: | Cardboard/PVC tube + PE film | Productivity: | 200,000 sqm / day |

| Brand: | Fibtex | Transportation: | Ocean,Land,Air,Fedex etc. |

| Place of Origin | Shandong, China | MOQ | 1x40HC |

| HS Code | 70195900.00 | Port: | Qingdao |